- info@ems-ltd.com

- 0118 9817391

Custom Designs

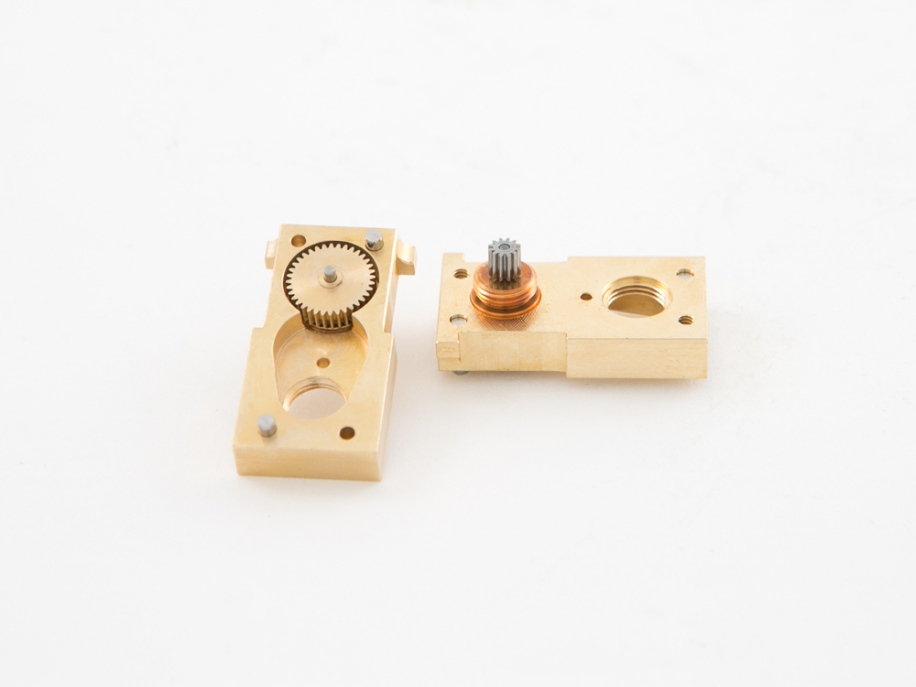

EMS custom drive system design

EMS isn’t only known for its supply of small DC motors and actuation systems from some of industry’s best known manufacturers. As well as our robust distribution offering, EMS manufactures custom drive systems for a range of applications out of our manufacturing facility in Poole, Dorset.

Our own manufacturing capabilities have grown year-on-year since first establishing the capability back in 1991. Today, supporting customers with bespoke drive solutions is a strategic part of our portfolio.

EMS now supplies custom electric drive systems to many industries including automotive, medical, metrology, aerospace, control and instrumentation, ergonomic home mobility equipment, the petrochemical industry, defence equipment, personal health and safety equipment and many others. These systems include custom gearbox design, but we can work closely with the customer to develop many other bespoke alternatives depending on your needs.

Why invest in a custom-designed electric drive system?

While standard drive products can often answer the customer's needs, sometimes the optimisation that comes with a custom design can result in a better overall solution both technically and economically. You may want to consider a custom drive system if:

You know you have limitations in space envelope — does your component need to be smaller, but with the same power requirements?

Does your drive system require a very specific configuration — is it desirable for the output of the drive system to be reversed back in a U-shaped configuration, for example?

Does your application require an optimised system that can reach a specific output performance?

Do you need to design simpler, yet highly effective, mechanical and electrical interfaces?

If your answer to any of these questions is yes, then a custom solution may be for you. You may also need a bespoke option without even realising yet — talking through your requirements with EMS means we can recommend the best route for your application, whether that’s an off-the-shelf drive system or an optimised custom alternative.

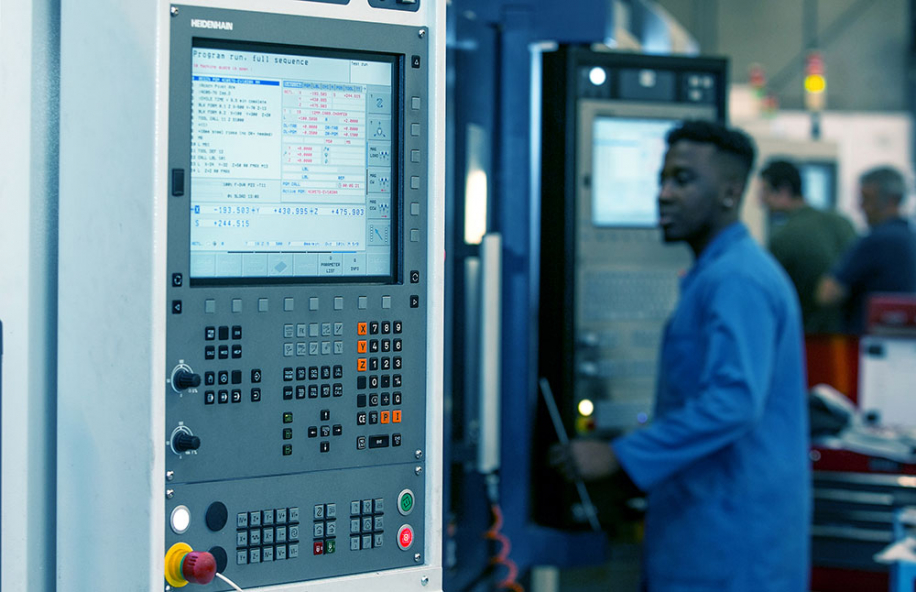

Optimised tools for optimised drive systems

Our manufacturing facility boasts a wealth of equipment and manufacturing techniques to bring your custom drive designs to life. On site, we have 27 CNC machining centres and lathes, as well as 55 gear cutting machines for producing spur, helical and worm gearing as designs require.

To provide customers with computer aided design (CAD) models of their bespoke gearboxes and other drive systems, EMS uses the latest 3D solid modelling and 2D design tools to craft clear, effective component designs. This ensures that, long before the metal is cut, the customer can assess the fit and function of the custom design and be assured the end product will function as they envisioned.

We’re also ISO9001:2015 accredited as part of our continuous dedication towards delivering the utmost quality to our customers.

Want to talk through your application’s requirements with our team of experts? If you think a custom drive option could be right for you, or if you’d just like to talk over your options, you can get in touch here.