- info@ems-ltd.com

- 0118 9817391

Home > PR > Ball screw spindle drive systems

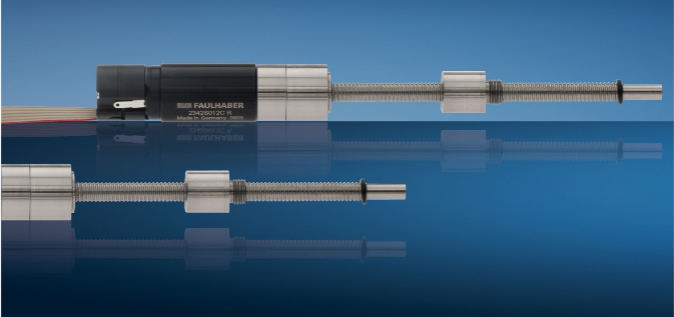

Ball screw spindle drive systems

Minimal pitch deviation for maximum precision

2nd August 2011

Filed under:

Faulhaber

Faulhaber high precision ball screws can now be integrated directly with their range of DC-Micro motors, Brushless DC-motors or Stepper motors. The series BS22-1.5 enables precise linear movements with minimum travel variations of just 5μm over the total travel. In combination with their highly efficient ironless rotor motor technology, high-resolution encoders and integrated motion controllers, maximum precision is guaranteed.

Mechanical interface to the motors is achieved with a backlash-free coupling integrated into the ball screw. The all stainless steel construction of the series BS22-1.5 offers intermittent axial forces up to 500N and speeds up to 125mm/s with a maximum efficiency of 89%. However this should only be considered as an entry level solution and countless modifications including screw length, modified ball nuts or special lubricants are available on request.

They are ideal for the most demanding linear positioning tasks such as optical filters, glass-fibre technology, lens adjustment in optical systems or micro actuators for medical technology.

Faulhaber products are distributed exclusively in the UK by miniature drives specialist Electro Mechanical Systems Ltd and for more information use our contact form or call 0118 9817391.

- Categories / Tags

- 1024...SR

- AEMT

- AESL

- Acceleration

- Agriculture

- Agritech

- Autoclave

- BHS

- BHT

- BHx

- BLDC

- BP4

- BRC Series

- BX4

- BXT

- BeBionic

- Bearings

- Bespoke

- Brushed

- Brushed DC Motors

- Brushless

- Brushless DC Motor

- Brushless DC Motors

- Brushless Dc Motors

- Brushless Motor

- Buhler

- Building Automation

- COVID

- CXR

- Catalogue

- Company Update

- Controller

- Coreless

- Coventry

- Custom

- Custom Design

- Custom Drive Design

- DC Motor

- DC Motor Supplier

- DMN

- Dc Motor

- Design

- Dimatech

- Drones

- EDS

- EMS

- EMS News

- EV

- Encoder

- Ewellix

- Exoskeleton

- Expo

- FAULHABER

- Factory

- Faulhaber

- Flat

- GPT

- Galil

- Gearhead

- IEF3

- IMC

- Industry 4.0

- Industry 4.0. Blog

- Inspection

- KAG

- LL06

- LM

- LVC

- Laboratory Automation

- Linear

- Linear Actuator

- Logistics

- M50

- M80

- MC3

- Maintenance

- Manufacturing

- Mechatronics

- MedTech

- Medical

- Medical Devices

- Medical Imaging

- Medtech

- Merkel

- Motion Control

- Motor

- Motor Supplier

- Neurosurgery

- New

- Nidec

- Nidec Servo

- Optical

- Pain Relief

- Piezo

- Piezomotor

- Pipeline

- Planetary

- Planetary Gearheads

- Point Of Care

- Precision

- Precistep

- Process

- Production

- Quickshaft

- Robot

- Robotics

- Robots

- SKF

- SR Series

- Samples

- Servomotors

- Small DC Motor

- Software

- Space

- Sponsorship

- Stepper

- Stepper Motor

- Stepper Motors

- TMS

- Testing

- Trade Show

- 1016

- 1660

- 1935

- 2017

- 2018

- 2020

- 2021