- info@ems-ltd.com

- 0118 9817391

Small DC motors for a variety of applications

EMS supplies a range of DC motors and actuation systems to fit a variety of applications. With partnerships with some of the world’s leading drive system suppliers, including FAULHABER, we can provide the drive system to meet your specifications.

Offering a range of brushed and brushless DC motors and actuation systems, EMS can meet the demands of any application. Some of the key sectors our products and services support include:

Medical

Micromotors are essential in medicine. Small DC motors are used to direct radiotherapy beams for effective treatment, as well as to drive prosthetics. Medical applications require micromotors capable of working to an extremely high precision. The motors must be able to deliver this level of performance over extended periods. With many medical devices operating continuously, a reliable motor is essential.

Healthcare

Healthcare is another sector that benefits from the power of motorisation. Devices may include protective equipment such as PPE masks. These masks have built-in fans to provide clean, contaminate-free air. They are particularly useful for clinical workers in environments where bacteria and viruses may be present. Other examples include motorised hospital beds and rehabilitation exoskeletons, built to improve patient comfort and aid recovery.

For such applications, compact and reliable motors are essential. Healthcare devices are often working continuously alongside patients. For this reason, motors with a silent or near-silent operation are pre-ferred. This minimises patient disturbance, and results in a quieter, more peaceful experience.

Industry

As manufacturers face increasing pressures to produce more products in less time, automation is key to meeting demand. Modern factories now include many technologies as standard, including conveyer belts and robotic arm grippers.

The demands placed on these motors are high. They must be able to work with high precision and be able to reposition quickly. Long operational lifetimes with high reliability are standard requirements to minimise downtime on the factory floor. They must also be easy to configure and integrate into new and existing systems.

Aerospace and aviation

Applications rarely get more demanding than those within aerospace and aviation. Here, DC motors could be responsible for controlling the flow of aircraft fuel or carefully positioning satellites in space.

Micromotors in these applications must be capable of withstanding extreme conditions. Harsh temperatures and severe shock and vibrations come as standard with the sector.

Furthermore, high reliability is essential. This is partly due to the critical roles that the motors play, but also because maintenance can be difficult to carry out regularly. This applies particularly to space applications.

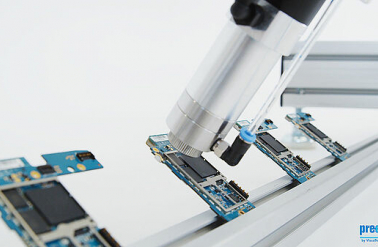

Precision measuring and testing

Testing can be carried out at any stage of the product’s lifetime. This could include analysing the raw material’s hardness and composition. For critical applications, extensive measuring and testing of the final product may be carried out to ensure it meets specifications.

Drive systems are a crucial part of testing equipment. DC motors move sample mounts and carefully align optical components for a thorough inspection. These motors must have high precision, with smooth adjustments to avoid errors in measurement.

Environmental and safety

In industry, there are frequently areas that are hazardous or hard-to-access. This often includes sites offshore or underground. In such sce-narios, robotics can provide the answer. Rather than relying on human operators to work in dangerous conditions, inspection robots can be employed. These robots can be controlled remotely and used to perform visual inspections.

Small DC robots are essential to allow the robot to work in small spaces. The motors must also be capable of dealing with harsh environments, including extreme temperatures and humidity. High power and torque are key to ensure the robot can move across more challenging terrain.

Optics

Many optical technologies and devices rely on micromotors to function. From aligning laser beams and driving thermal cameras to powering microscopes and telescopes, micromotors are crucial in enabling their functionality.

These motors must work with precision, while maintaining a low weight to ensure device portability. The ability to change direction quickly is essential for fast focusing, desired in many optical applications.

Your small DC motors from EMS

With more than 30 years of experience supplying the market across the UK and Ireland, EMS has vast experience in specifying and supplying actuation systems for all applications. To discuss your application and requirements, get in touch with a member of the team today.