- info@ems-ltd.com

- 0118 9817391

Home > Custom design > Die casting

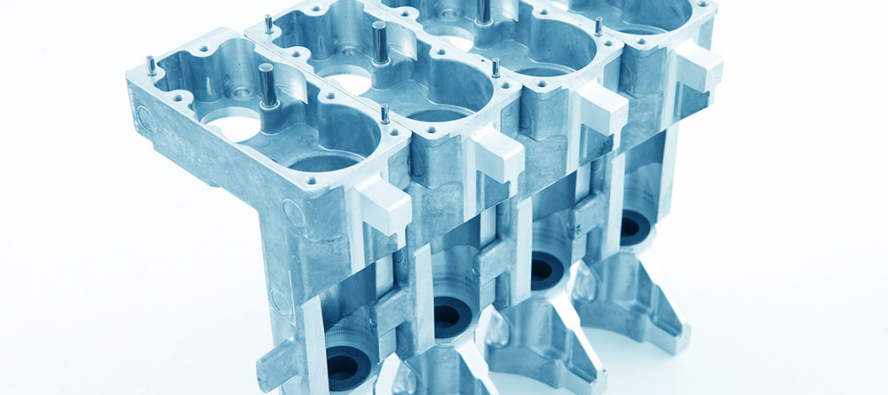

Die Casting

Design choices and manufacturing techniques will be dictated to some extent by the potential volume required and each can be explored during the concept phase to satisfy application volumes starting in the low hundreds.

Zinc die casting is often used for higher volume applications to manufacture custom gearbox housings. Die casting involves forcing molten metal under high pressure into a mould cavity, producing high quality finished goods. The ease and high performance of this manufacturing technique along with the long tool life and precision gear design and assembly allows EMS to produce products with production runs exceeding 50,000 units per year. Depending on the precision of the casting this process can negate the need for post machining of critical features, resulting in a cost effective solution.