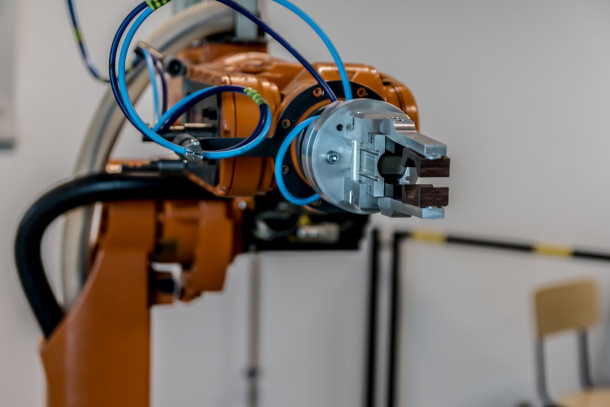

Real world applications of precision DC motors and drive systems

Offering a range of brushed motors, brushless DC motors and actuation systems, EMS can meet the demands of even the most specialist applications. With partnerships with some of the world’s leading drive system suppliers, including FAULHABER, we provide the drive system to meet your specifications.

Some of the key sectors our products and services support include: