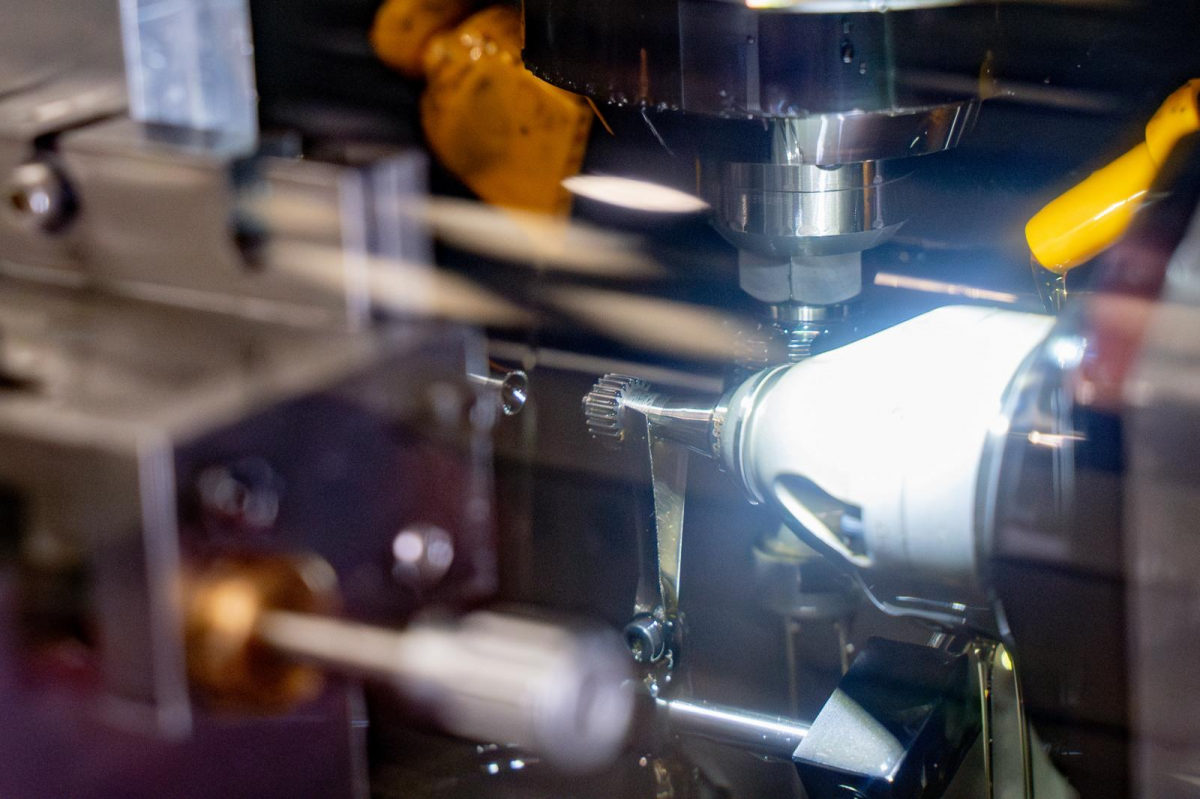

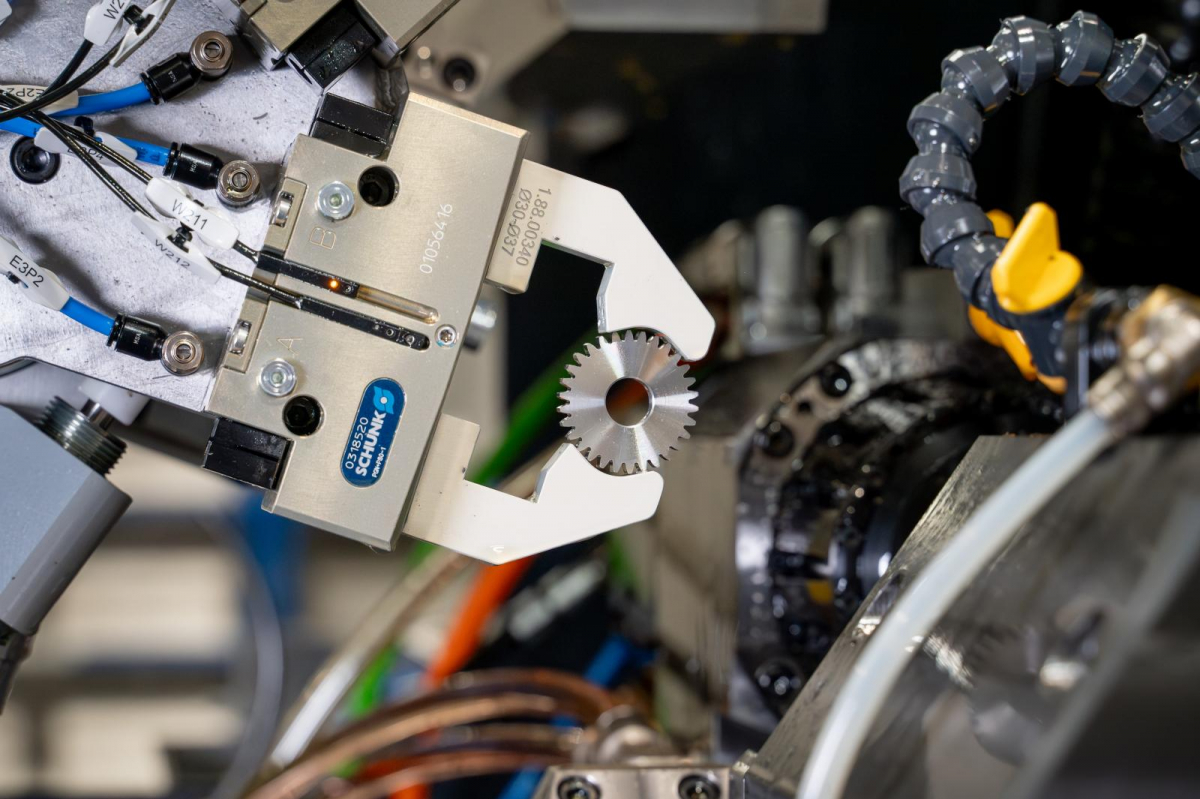

End of line testing capability

As part of our commitment to quality and precision manufacturing, EMS provides bespoke end-of-line (EOL) testing as the final quality assurance step. Our EOL testing capability means we minimise errors, reducing the cost of rework and returns, ensures regulatory compliance and guarantees customer satisfaction.

EOL testing is fully integrated into customer-specific assembly cells and is tailored to meet the precise performance and compliance requirements of each application. To ensure the optimal solution without any defects, our EOL testing enables us to:

- Verify mechanical and electrical performance

- Monitor noise levels

- Validate component assembly

- Optimise flow benches

- Test unique requirements to level of control and quality

By implementing high-precision, application-specific testing protocols, we ensure all products meet stringent regulatory requirements — a particularly critical aspect for medical, aerospace and mission-critical applications.